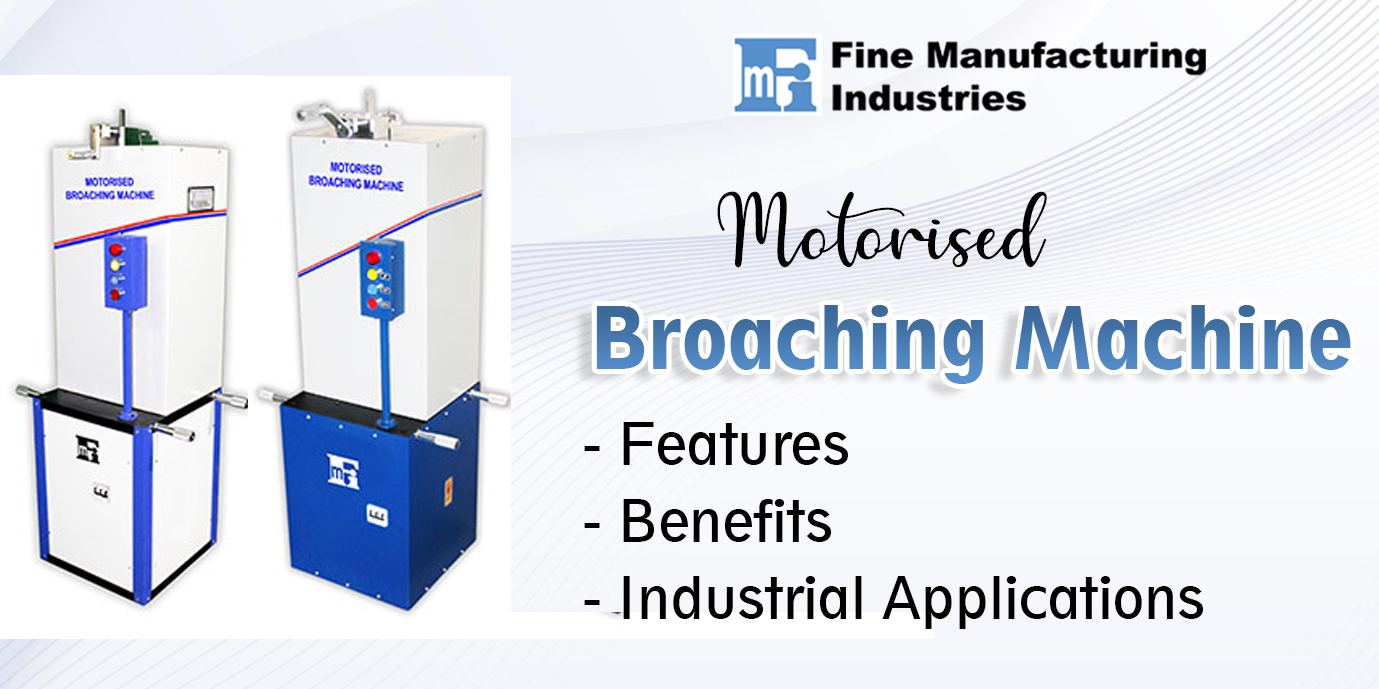

Motorised Broaching Machine: Features, Benefits, and Industrial Applications

A Motorised Broaching Machine is widely used in modern manufacturing industries for producing accurate internal and external profiles in metal components. With growing demand for precision engineering and faster production cycles, broaching machines have become essential equipment in automotive, aerospace, and heavy engineering sectors.

This guide explains the working principle, features, benefits, applications, and maintenance practices of motorised broaching machines to help industries understand why these machines are crucial for efficient production.

What is a Motorised Broaching Machine?

A motorised broaching machine is a machining system in which a motor drives a multi-tooth cutting tool known as a broach across or through a workpiece. Each tooth removes a small amount of material, gradually forming the desired shape in a single pass.

Unlike traditional machining processes that require multiple operations, broaching produces accurate shapes quickly and efficiently.Motorised machines improve productivity by automating the broaching process and reducing manual effort.

These machines are suitable for medium to high-volume production where consistency and precision are required.

How Does a Motorised Broaching Machine Work?

In a motorised broaching system:

- 1. The workpiece is securely clamped on the machine fixture.

- 2. The broach tool moves through or over the component using motor power.

- 3. Multiple cutting teeth gradually remove material.

- 4. The final tooth produces the required profile with high precision.

- 5. Finished components are produced in one continuous stroke.

This method ensures fast machining while maintaining uniform accuracy across production batches.

Key Features of Motorised Broaching Machines

Modern motorised broaching machines offer several advanced features:

- • High-performance motor-driven operation

- • Smooth cutting with minimal vibration

- • Compact and sturdy machine construction

- • Adjustable stroke lengths

- • Easy tool setup and changeover

- • Enhanced safety systems

- • Energy-efficient operation

- • Low maintenance requirements

- • High machining accuracy

These features help manufacturers maintain productivity and consistent product quality.

Benefits of Motorised Broaching Machines

High Production Speed

Broaching completes machining in a single pass, making it much faster than milling or shaping processes.

Precision Machining

The process produces consistent and accurate profiles across large production batches.

Reduced Labor Requirement

Motorised systems minimize manual involvement, improving operator productivity.

Cost Efficiency

Faster production and reduced tool wear lower overall manufacturing costs.

Consistent Quality Output

Broaching ensures uniform component dimensions and surface finish.

Versatile Machining Capability

One machine can perform multiple operations using different broach tools.

Industrial Applications of Motorised Broaching Machines

Motorised broaching machines are widely used across industries, including:

Automotive Industry

Production of gears, steering components, transmission parts, and engine components.

Aerospace Industry

Manufacturing of high-precision aircraft components requiring strict dimensional accuracy.

Heavy Machinery Manufacturing

Broaching of shafts, hubs, and machine components.

Hydraulic and Pneumatic Equipment

Creation of splines and slots in hydraulic parts.

Tool and Die Industry

Used in the production of molds, dies, and precision tooling.

Defense and Railways

- • Manufacturing heavy-duty components requiring high strength and precision.

- • Because of their versatility, broaching machines are essential in many manufacturing sectors.

Maintenance Tips for Motorised Broaching Machines

Regular maintenance ensures long machine life and consistent performance.

Regular Lubrication

Lubricate moving components to reduce wear and friction.

Tool Inspection

Inspect broach tools frequently for wear and damage.

Machine Alignment Check

Ensure proper alignment for accurate cutting results.

Clean Machine after Use

Remove chips and debris to prevent operational issues.

Replace Worn Parts Promptly

- Avoid machine breakdown by replacing damaged components early.

- Proper maintenance reduces downtime and increases machine life.

Factors to Consider When Buying a Motorised Broaching Machine

Before investing in a broaching machine, industries should consider:

- Required production volume

- Workpiece size and material type

- Machine stroke length capacity

- Accuracy requirements

- Machine durability

- Manufacturer support and service availability

- Spare parts availability

- Operator safety features

- Energy efficiency

Choosing the right machine improves productivity and operational reliability.

Latest Trends in Broaching Machine Technology

Manufacturers are introducing advanced technologies to improve broaching operations:

- CNC-controlled broaching systems

- Automation and robotic integration

- Energy-efficient motors

- Improved tool materials for longer life

- Smart monitoring systems

- Reduced vibration technology

These advancements enhance precision and reduce maintenance needs.

Why Choose a Reliable Manufacturer?

A trusted manufacturer ensures:

- Machine reliability

- Proper installation support

- Operator training

- Spare parts availability

- Technical assistance

- Long-term machine performance

Partnering with an experienced supplier improves production efficiency and reduces downtime.

Conclusion

A Motorised Broaching Machine plays a critical role in precision manufacturing industries. Its ability to produce accurate profiles quickly makes it ideal for large-scale industrial production.

With proper maintenance and machine selection, manufacturers can improve productivity, maintain quality standards, and reduce operational costs. Investing in a reliable broaching solution ensures long-term manufacturing success.

Contact Us – Fine Manufacturing

For high-performance Motorised Broaching Machines, contact Fine Manufacturing today for expert solutions and reliable industrial support.

FAQs

It is used to create precise internal and external shapes such as keyways, splines, and slots in industrial components.

Automotive, aerospace, heavy engineering, railways, and machinery manufacturing industries widely use them.

Broaching offers faster machining, higher accuracy, and consistent production quality in a single pass.

Regular inspection and maintenance are recommended based on production load, typically every few months.

Yes, they are ideal for medium to high-volume production due to their speed and precision.

Materials like steel, aluminum, brass, cast iron, and other industrial metals can be broached.